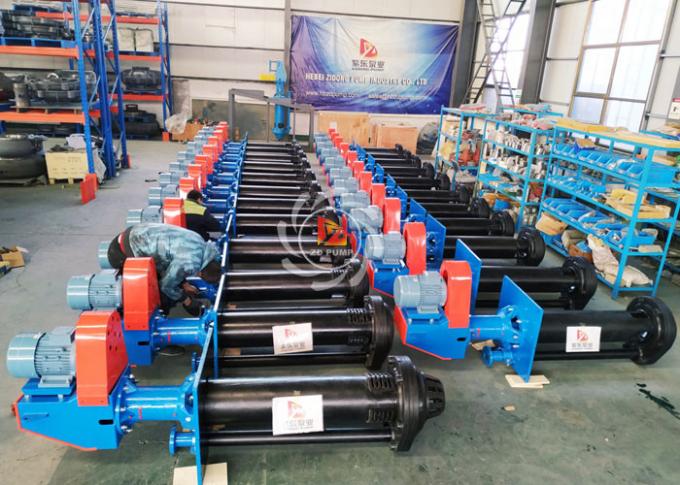

65QV-ZP Vertical Slurry Pump is designed to handle diverse uses including all rugged mining and industrial applications, always ensuring reliable performance and excellent wear endurance.

65QV-ZP vertical sump pumps are available in various standard lengths to suit common sump depths, offers a wide range of configurations allowing the pump to be tailored to a specific application.

Wetted components are available in a wide range of alloys and elastomers. They are ideally suited for handling abrasive and corrosive liquids and slurries while submerged in sumps or pits.

| Model |

Matching power P(kw) |

Capacity Q(m3/h) |

Head H(m) |

Speed n(r/min) |

Eff.η(%) |

Impeller dia.(mm) |

Max.particles(mm) |

Weight(kg) |

| 65QV-ZP(R) | 3-30 | 18-113 | 5-31.5 | 700-1500 | 60 | 280 | 15 | 500 |

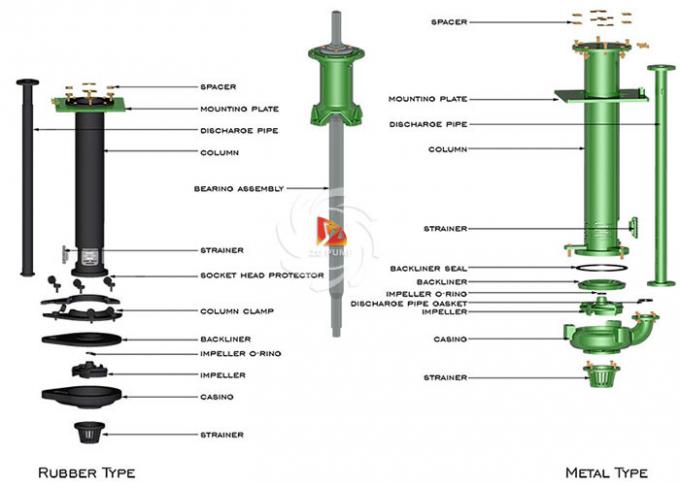

Wet parts of type ZP pump are made of abrasion-resistant metal.

All parts of type ZPR pump immersed in liquid are lined with rubber outer liner. They are suited to transport no-edge angle abrasive slurry.

| Metal Lined Vertical Slurry Pump | Rubber Lined Vertical Slurry Pump | ||||

| No | Parts name | Materials | No | Parts name | Materials |

| 1 | Shaft | 45 High Strength Steel | 1 | Shaft | 45 High Strength Steel |

| 2 | Bearing | China Brand or SKF; NSK | 2 | Bearing | China Brand or SKF; NSK |

| 3 | Bearing Housing | HT250 | 3 | Bearing Housing | HT250 |

| 4 | Bearing spacer | Stainless Steel | 4 | Bearing spacer | Stainless Steel |

| 5 | Bearing | China Brand or SKF; NSK | 5 | Bearing | China Brand or SKF; NSK |

| 6 | Shim | Stainless steel | 6 | Shim | Stainless steel |

| 7 | Column | Stainless steel | 7 | Column | Stainless steel |

| 8 | Strainer | Cast Iron | 8 | Strainer | Natural Rubber |

| 9 | Back liner | Ultra Chrome Alloy | 9 | Back liner | Anti-abrasive Rubber |

| 10 | Impeller | Ultra Chrome Alloy | 10 | Impeller | Anti-abrasive Rubber |

| 11 | Pump casing | Ultra Chrome Alloy | 11 | Pump casing | Anti-abrasive Rubber |

| 12 | Lower strainer | Cast Iron | 12 | Lower strainer | Natural Rubber |

| 13 | Discharge pipe | Stainless steel | 13 | Discharge pipe | Stainless steel |

| 14 | Flushing pipe | Carbon steel | 14 | Flushing pipe | Carbon steel |

| 15 | Coupling | 45# Steel | 15 | Coupling | 45# Steel |

| 16 | Middle supporting parts | Stainless steel | 16 | Middle supporting parts | Stainless steel |

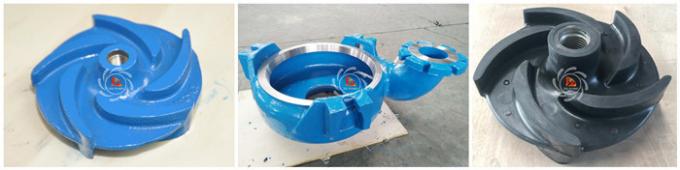

Less wear, less corrosion

Wetted components are available in a wide range of alloys and elastomers. Zidong selects the optimum combination of materials for maximum resistance to wear in virtually any industrial application, including those demanding both abrasion and corrosion resistance, and where larger particles or high density slurries are encountered.

- Abrasion resistant Ultra chrome® A05 alloy.

- Abrasion/corrosion-resistant Hyper chrome® A49 alloy.

- Corrosion-resistant stainless steels.

- Natural and synthetic elastomer.

No submerged bearing failures

The robust cantilever shaft avoids the need for lower submerged bearings which are often the source of premature bearing failure.

- Heavy duty roller bearings, above mounting plate.

- No submerged bearings.

- Labyrinth/flinger bearing protection.

- Rigid, large diameter shaft.

No shaft sealing problems

The vertical cantilever design requires no shaft seal.

No priming required.

The top and bottom inlet design is ideally suited for “snore” conditions.

Less risk of blocking

The screened inlets and large impeller passages reduce the risk of blockages.

Zero ancillary water costs

The vertical cantilever design with no gland or submerged bearings avoids the need for expensive gland or bearing flushing water.

| ZP/ ZPR CLEAR WATER PERFORMANCE | ||||||||

| MODEL | MAX. POWER (KW) |

MATERIAL | Q CAPACITY | HEAD H(m) |

SPEED n(r/min) |

MAX. Eff η% |

||

| LINER | IMPEL | (m 3 /h) | (I/S) | |||||

| ZP-40PV | 15 | M | M or RU | 19.44~43.2 | 5.4~12 | 4.5~28.5 | 1000~2200 | 40 |

| ZPR-40PV | 15 | RU | RU | 17.28~39.6 | 4.8~11 | 4~26 | 1000~2200 | 40 |

| ZP-65QV | 30 | M | RU | 23.4~111 | 6.5~30.8 | 5~29.5 | 700~1500 | 50 |

| ZP-65QV | 30 | M | M | 19.8~93.06 | 5.5~25.85 | 5~29.5 | 700~1500 | 40 |

| ZP-65QV | 30 | M | M | 23.4~87.12 | 6.75~24.2 | 5.5~31.5 | 700~1500 | 58 |

| ZPR-65QV | 30 | RU | RU | 22.5~105 | 6.25~29.15 | 5.5~31.5 | 700~1500 | 51 |

| ZP-65QV | 30 | M | M | 18.9~89.1 | 5.25~24.75 | 5~28 | 700~1500 | 35 |

| ZP-100RV | 75 | M | RU | 56.7~221.76 | 15.75~61.9 | 4.5~34.5 | 500~1200 | 56 |

| ZP-100RV | 75 | RU | RU | 64.8~285 | 18~79.2 | 7.5~36 | 600~1200 | 62 |

| ZPR100RV | 75 | M | M | 54~289 | 15~80.3 | 5~35 | 500~1200 | 56 |

| ZP-100RV | 75 | M | M | 54~237.6 | 15~66 | 6~30 | 600~1200 | 40 |

| ZP-150SV | 110 | M | RU | 108~479.16 | 30~133.1 | 8.5~40 | 500~1000 | 52 |

| ZP-200SV | 110 | M | M or RU | 189~891 | 52.5~247.5 | 6.5~37 | 400~850 | 64 |

| ZP-250TV | 200 | M | M or RU | 261~1089 | 72.5~302.5 | 7.5~33.5 | 400~750 | 60 |

| ZP-300TV | 200 | M | RU | 288~1267 | 80~352 | 6.5~33 | 350~700 | 50 |

● Minerals processing

● Coal preparation

● Chemical processing

● Effluent handling

● Sand and gravel

● Abrasive and/or corrosive slurries

● Large particle sizes

● High density slurries

● Heavy duties demanding cantilever shafts