We have automated casting production lines, CNC machining center, modern assembly workshops, spray-baking equipment, and large pump testing center.

6 rich-experienced engineers, more than 20 skilled workers with over 10 years working time, and professional QC workers. To ensure that the quality is controlled from the source,and the actual test data is been used as a reliable basis to ensure that every pump and parts meet international high standard requirements.

Shape Guarantee

Large parts adopt aluminum mold to ensure casting flatness.

Small parts adopt precision casting of wax mold to ensure real international standard.

Material Guarantee

Sample piece can be cast on part to ensure material truth.

Sample piece can be cut down to be inspected by third lab, or in clients’ side.

Hardness Guarantee

Hardness inspection before delivery to ensure hardness over 60HRC.

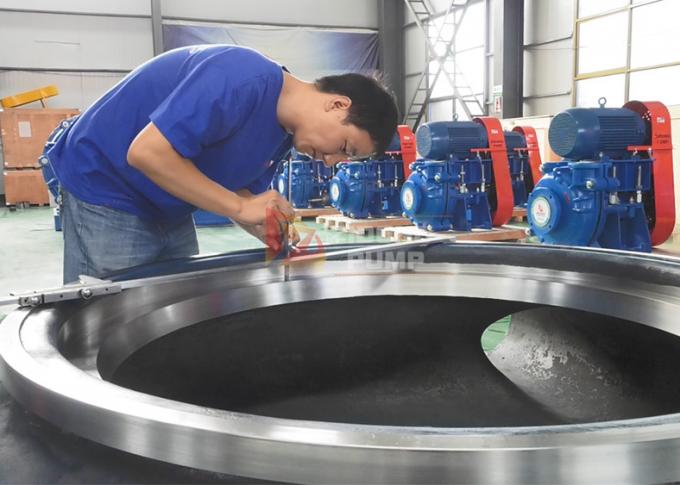

Defective and Dimension Guarantee

Professional QC engineer inspects internal and external of each part strictly to ensure no defective, no dimension tolerances to replace your old parts.

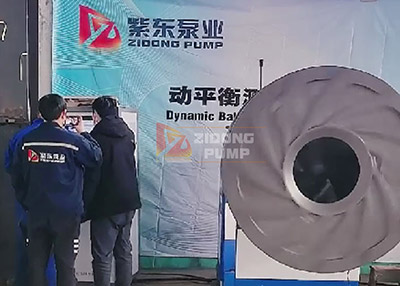

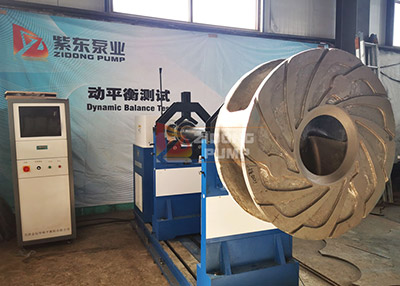

Impeller dynamic balance

Impeller dynamic balance to ensure impeller stable running.

Surface Guarantee

Spray-baking technique to ensure painting surface gloss and artwork feature.

Performance Guarantee

Performance test before delivery to ensure over the performance of the client’s requirements.

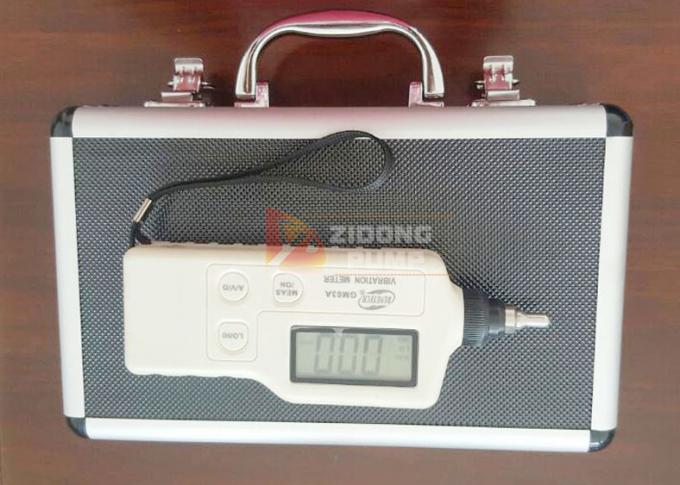

Zidong Pump Quality Inspection Equipment

In past years, we won project bid from U.N.