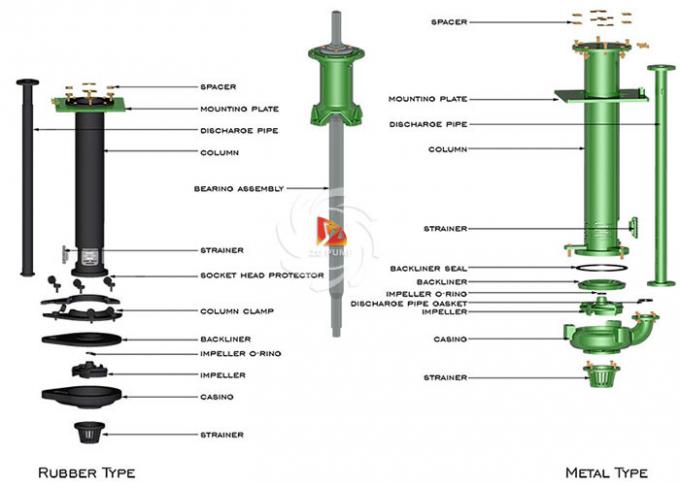

Type ZP(R) pumps are vertical, centrifugal slurry pumps submerged in sump to work. They are designed for delivering abrasive, large particle and high density slurries. These pumps have no need of any shaft seal and sealing water. They can also be operated normally for insufficient suction duties, which is suited for the working condition of deeper level. The guide bearing construction is added to the pump on the basis of the standard pump, so the pump is with both more steady operation and wider application range, but flushing water should be attached to the guide bearing.

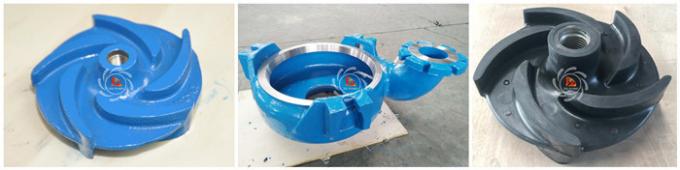

Wet parts of type ZP pump are made of abrasion-resistant metal.

All parts of type ZPR pump immersed in liquid are lined with rubber outer liner. They are suited to transport no-edge angle abrasive slurry.

CANTILEVERED SHAFT

The standard ZP(R) pumps feature a cantilevered shaft which is up to 2400mm long. The cantilevered shaft means that there is no shaft sealing requirement and the drive end bearings do not come into contact with any pumped product. This reduces the risk of bearing failure and extends the wear life of the pumps.

HEAVY DUTY WET END

Wet end components are manufactured from high quality 27% chrome white iron or rubber coated steel for exceptional wear resistance and service life with minimal corrosion. The heavy duty design can pump high density and abraisive slurries and the large passages of the impeller allows the transfer of large particles without blockages in a wide range of mining, processing and heavy industrial applications. Wet end stub shaft options are available to suit severe duty applications.

COLUMN AND DISCHARGE PIPES

Column and discharge pipes are available in a range of materials to suit the requirements of operators. Standard options include mild steel and rubber lined mild steel. Composite options are available.

VERSATILE DRIVE OPTIONS

ZP(R) pumps can be directly driven using electric motors or belt driven with either set speed or variable speed operation.

REMOVABLE STRAINERS

ZP(R) pumps feature rubber or cast iron upper strainers and cast iron lower strainers to prevent blockages. The strainers are easily removed for servicing or replacement.

“L” MODELS EXTENDED SHAFT

The extended shaft “L” model features column bearings and shaft seal which further extends the pumping depth and enables the transfer of slurries from deeper sumps and pits.

| ZP/ ZPR CLEAR WATER PERFORMANCE | ||||||||

| MODEL | MAX. POWER (KW) |

MATERIAL | Q CAPACITY | HEAD H(m) |

SPEED n(r/min) |

MAX. Eff η% |

||

| LINER | IMPEL | (m 3 /h) | (I/S) | |||||

| ZP-40PV | 15 | M | M or RU | 19.44~43.2 | 5.4~12 | 4.5~28.5 | 1000~2200 | 40 |

| ZPR-40PV | 15 | RU | RU | 17.28~39.6 | 4.8~11 | 4~26 | 1000~2200 | 40 |

| ZP-65QV | 30 | M | RU | 23.4~111 | 6.5~30.8 | 5~29.5 | 700~1500 | 50 |

| ZP-65QV | 30 | M | M | 19.8~93.06 | 5.5~25.85 | 5~29.5 | 700~1500 | 40 |

| ZP-65QV | 30 | M | M | 23.4~87.12 | 6.75~24.2 | 5.5~31.5 | 700~1500 | 58 |

| ZPR-65QV | 30 | RU | RU | 22.5~105 | 6.25~29.15 | 5.5~31.5 | 700~1500 | 51 |

| ZP-65QV | 30 | M | M | 18.9~89.1 | 5.25~24.75 | 5~28 | 700~1500 | 35 |

| ZP-100RV | 75 | M | RU | 56.7~221.76 | 15.75~61.9 | 4.5~34.5 | 500~1200 | 56 |

| ZP-100RV | 75 | RU | RU | 64.8~285 | 18~79.2 | 7.5~36 | 600~1200 | 62 |

| ZPR100RV | 75 | M | M | 54~289 | 15~80.3 | 5~35 | 500~1200 | 56 |

| ZP-100RV | 75 | M | M | 54~237.6 | 15~66 | 6~30 | 600~1200 | 40 |

| ZP-150SV | 110 | M | RU | 108~479.16 | 30~133.1 | 8.5~40 | 500~1000 | 52 |

| ZP-200SV | 110 | M | M or RU | 189~891 | 52.5~247.5 | 6.5~37 | 400~850 | 64 |

| ZP-250TV | 200 | M | M or RU | 261~1089 | 72.5~302.5 | 7.5~33.5 | 400~750 | 60 |

| ZP-300TV | 200 | M | RU | 288~1267 | 80~352 | 6.5~33 | 350~700 | 50 |

● Minerals processing

● Coal preparation

● Chemical processing

● Effluent handling

● Sand and gravel

● Abrasive and/or corrosive slurries

● Large particle sizes

● High density slurries

● Heavy duties demanding cantilever shafts