Zidong Pump® ZP150SV Vertical Sump Pumps are designed for every other tank, pit or hole-in-the-ground slurry handling situation, ZP150SV pumps are available in various standard lengths to suit common sump depths, for very deep sumps or where high shaft speeds limit the length of the pump, a suction extension pipe can be fitted to the bottom inlet to extend the depth of the pump by up to 2 meters.

150SV-ZP Vertical Slurry Pump is available in a wide range of popular sizes to suit most pumping applications. Thousands of these pumps are proving their reliability and efficiency worldwide in Minerals processing, Coal preparation, Chemical processing, Effluent handling, Sand and gravel and almost every other tank, pit or hole-in-the ground slurry handling situation.

| Model |

Matching Power P(kw) |

Capacity Q(m3/h) |

Head H(m) |

Speed N(r/min) |

Eff.η(%) |

Impeller Dia.(mm) |

Max.Particles(mm) |

Weight(kg) |

| 150SV-ZP(R) | 11-110 | 108-576 | 8.5-40 | 500-1000 | 52 | 450 | 45 | 1737 |

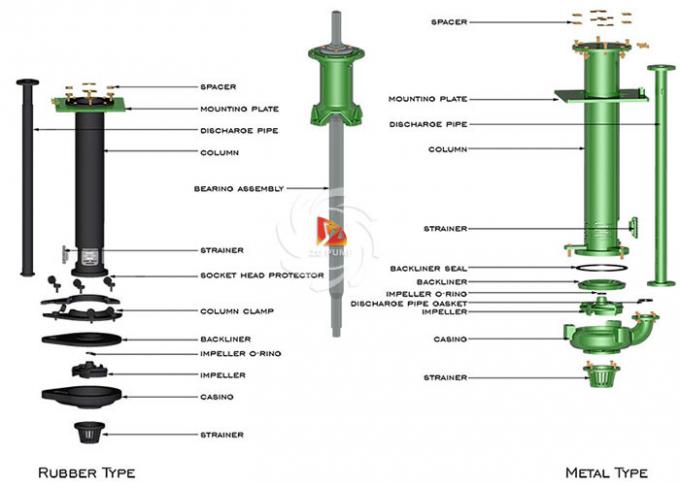

Wet parts of type ZP pump are made of abrasion-resistant metal.

All parts of type ZPR pump immersed in liquid are lined with rubber outer liner. They are suited to transport no-edge angle abrasive slurry.

| Metal Lined Vertical Slurry Pump | Rubber Lined Vertical Slurry Pump | ||||

| No | Parts name | Materials | No | Parts name | Materials |

| 1 | Shaft | 45 High Strength Steel | 1 | Shaft | 45 High Strength Steel |

| 2 | Bearing | China Brand or SKF; NSK | 2 | Bearing | China Brand or SKF; NSK |

| 3 | Bearing Housing | HT250 | 3 | Bearing Housing | HT250 |

| 4 | Bearing spacer | Stainless Steel | 4 | Bearing spacer | Stainless Steel |

| 5 | Bearing | China Brand or SKF; NSK | 5 | Bearing | China Brand or SKF; NSK |

| 6 | Shim | Stainless steel | 6 | Shim | Stainless steel |

| 7 | Column | Stainless steel | 7 | Column | Stainless steel |

| 8 | Strainer | Cast Iron | 8 | Strainer | Natural Rubber |

| 9 | Back liner | Ultra Chrome Alloy | 9 | Back liner | Anti-abrasive Rubber |

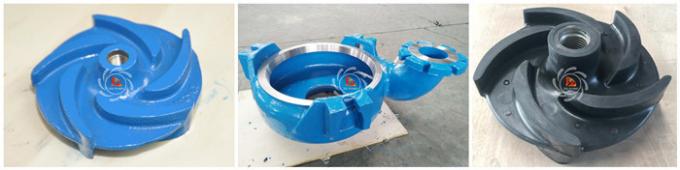

| 10 | Impeller | Ultra Chrome Alloy | 10 | Impeller | Anti-abrasive Rubber |

| 11 | Pump casing | Ultra Chrome Alloy | 11 | Pump casing | Anti-abrasive Rubber |

| 12 | Lower strainer | Cast Iron | 12 | Lower strainer | Natural Rubber |

| 13 | Discharge pipe | Stainless steel | 13 | Discharge pipe | Stainless steel |

| 14 | Flushing pipe | Carbon steel | 14 | Flushing pipe | Carbon steel |

| 15 | Coupling | 45# Steel | 15 | Coupling | 45# Steel |

| 16 | Middle supporting parts | Stainless steel | 16 | Middle supporting parts | Stainless steel |

● Cantilever design without submerged bearings or shaft seals;

● Wet components are available in A05 high chrome alloy and elastomer (rubber);

● The screened inlets and large impeller passages reduce the risk of blockages;

● Available in a pre-fabricated conical sump with quick clean facilities;

● Replaceable strainers allows for easy maintenance;

● Simple installation and easy maintenance.

● Anti-wear, anti-corrosion, which let the pumps service more longer;

● No priming required.

| ZP/ ZPR CLEAR WATER PERFORMANCE | ||||||||

| MODEL | MAX. POWER (KW) |

MATERIAL | Q CAPACITY | HEAD H(m) |

SPEED n(r/min) |

MAX. Eff η% |

||

| LINER | IMPEL | (m 3 /h) | (I/S) | |||||

| ZP-40PV | 15 | M | M or RU | 19.44~43.2 | 5.4~12 | 4.5~28.5 | 1000~2200 | 40 |

| ZPR-40PV | 15 | RU | RU | 17.28~39.6 | 4.8~11 | 4~26 | 1000~2200 | 40 |

| ZP-65QV | 30 | M | RU | 23.4~111 | 6.5~30.8 | 5~29.5 | 700~1500 | 50 |

| ZP-65QV | 30 | M | M | 19.8~93.06 | 5.5~25.85 | 5~29.5 | 700~1500 | 40 |

| ZP-65QV | 30 | M | M | 23.4~87.12 | 6.75~24.2 | 5.5~31.5 | 700~1500 | 58 |

| ZPR-65QV | 30 | RU | RU | 22.5~105 | 6.25~29.15 | 5.5~31.5 | 700~1500 | 51 |

| ZP-65QV | 30 | M | M | 18.9~89.1 | 5.25~24.75 | 5~28 | 700~1500 | 35 |

| ZP-100RV | 75 | M | RU | 56.7~221.76 | 15.75~61.9 | 4.5~34.5 | 500~1200 | 56 |

| ZP-100RV | 75 | RU | RU | 64.8~285 | 18~79.2 | 7.5~36 | 600~1200 | 62 |

| ZPR100RV | 75 | M | M | 54~289 | 15~80.3 | 5~35 | 500~1200 | 56 |

| ZP-100RV | 75 | M | M | 54~237.6 | 15~66 | 6~30 | 600~1200 | 40 |

| ZP-150SV | 110 | M | RU | 108~479.16 | 30~133.1 | 8.5~40 | 500~1000 | 52 |

| ZP-200SV | 110 | M | M or RU | 189~891 | 52.5~247.5 | 6.5~37 | 400~850 | 64 |

| ZP-250TV | 200 | M | M or RU | 261~1089 | 72.5~302.5 | 7.5~33.5 | 400~750 | 60 |

| ZP-300TV | 200 | M | RU | 288~1267 | 80~352 | 6.5~33 | 350~700 | 50 |

● Mining and mineral processing process and spillage sump duties

● Mill scale pumping in steel mills

● Sugar cane processing

● Non-contact induced-flow pumping of impact-sensitive media like carbon transfer or froth (when provided with an optional recessed vortex impeller)