Zidong sand gravels pumps(manufactured by china directly top factory of Zidong) are designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumps by a common slurry pump.The pump body(casing & impeller) made of 27% high chrome alloy, the extra thick pump case let the pump anti-wear and need lowest maintenance cost.

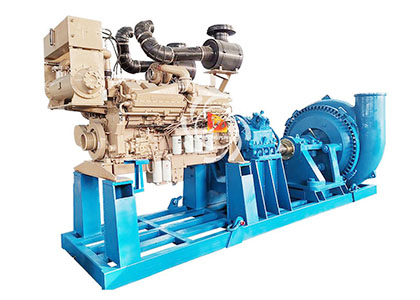

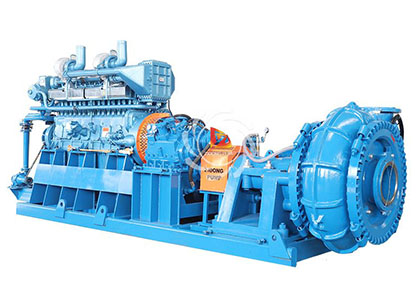

ZG(H) Series Sand Gravel Pump is horizontal single-casing gravel pump with wide channel to transfer sand, slurries or gravels with big particle size. The wet parts are made of Ni-hard and high-Chrome alloys to ensure long service life. It has superior performance than common pumps in dredging, sand mining, barge loading and mineral processing etc.

• Our ZG,ZGH sand gravel pumps are the series products introduced from international high technique. All spare parts are 100% replaced with international parts.

• Zidong sand pumps are designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumps by a common slurry pump.

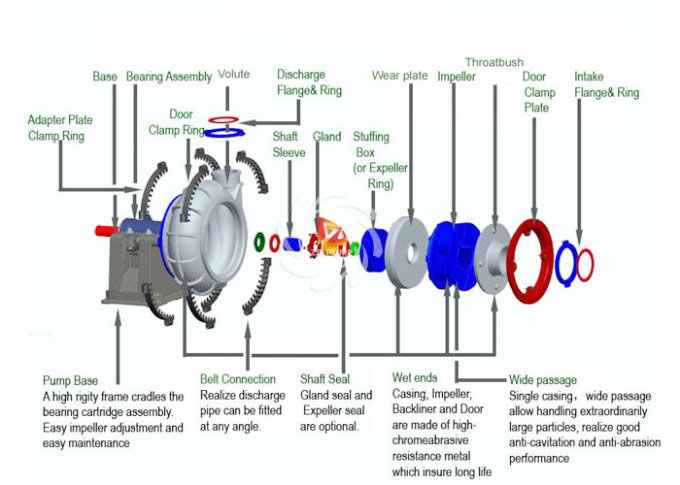

• Construction of this pump is of single casing connected by means of clamp bands and wide wet-passage.

• The wet-parts are made of Ni-hard high chrom abrasion-resistance alloy.

• The discharge direction of pump can be oriented in any direction of 360°.

• This type of pump possesses the advantages of easy installation and operation, good performance of NPSH and abrasion resistance.

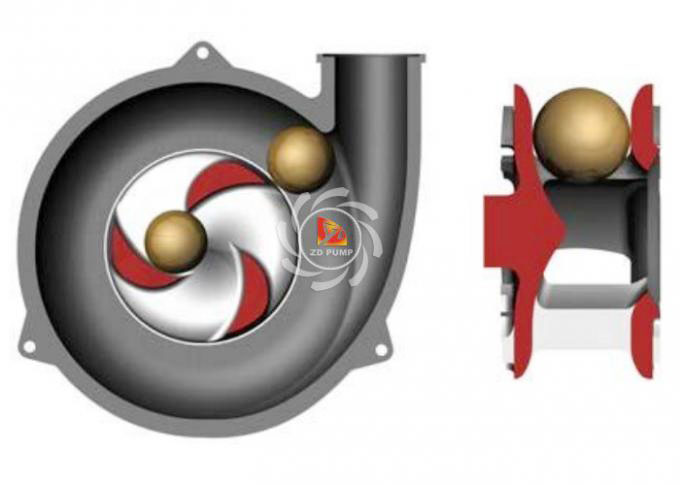

• 3 Vanes big passing channel with extra thick wall.

• Bearing Assembly – A large diameter shaft with short overhang minimizes deflection & contributes to long bearing life.

• Casing – Single casing be made of high-chrome alloy, provide long wear time.

• Impeller – 3 vanes impeller, processing larger solids easily. The impeller and casing are threaded connection,no need nuts.

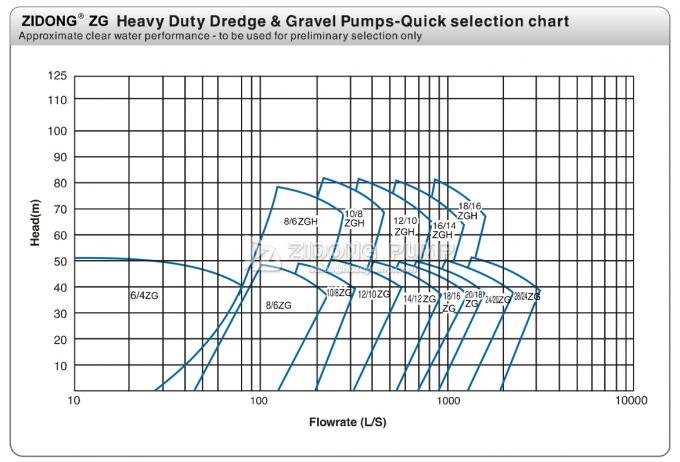

High efficiency and high head designs are also available.

• Cover Plate – Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

• One-Piece Frame – A very robust one-piece frame cradles the cartridge type bearing and shaft assembly.

An external impeller adjustment mechanism is provided for easy adjustment of impeller clearance

| Model | ZG Series Clear Water Performance | ||||||

| Max. Power (kw) |

Capacity (m3/h) |

Head (m) |

Speed (r/min) |

Max. Eff% |

NPSH (m) |

Max Size Passage (mm) |

|

| ZG-6×4D | 60 | 36-250 | 3.5-51 | 600-1400 | 50 | 3.5 | 82 |

| ZG-8×6E | 120 | 180-540 | 10-48 | 800-1400 | 50 | 4.5 | 127 |

| ZG-10×8F | 260 | 180-820 | 13-50 | 500-1000 | 65 | 7.5 | 178 |

| ZG-10×8S | 560 | 180-820 | 13-50 | 500-1000 | 65 | 7.5 | 178 |

| ZG-12×10G | 600 | 360-1200 | 11-58 | 400-850 | 70 | 4.5 | 220 |

| ZG-14×12G | 600 | 500-3000 | 6-66 | 300-700 | 68 | 4.5 | 241 |

| ZGH-10×8S | 560 | 750-1300 | 18-80 | 500-950 | 68 | 7.5 | 180 |

| ZGH-12×10G | 600 | 1400-2700 | 28-78 | 350-700 | 72 | 8 | 210 |

| ZG-16/14G | 600 | 720-3600 | 18-45 | 300-500 | 70 | 3-9 | 230 |

| ZGH-16×14TU | 1200 | 700-3400 | 20-72 | 300-500 | 72 | 3-6 | 230 |

| ZG-18×16TU | 1200 | 700-4320 | 12-48 | 250-500 | 72 | 3-6 | 254 |

They are suitable for deliverinng slurries in Mining, Explosive-sludge in metal melting, dredging in dredger and course of rivers, and other fieldes.

• Sand and gravel

• Hydraulic mining

• Slag granulation

• Tunneling

• River and pond dredging

• Heavy refuse removal

• Large particle or low NPSHA applications