| Size(discharge) | 8″(200 Mm) | Capacity | 6.3-400 M 3/h |

|---|---|---|---|

| Head | 5-80m | Material | Fluorine-plastic Alloy |

| Seed | 1450&2900 R / Min | Motor Power | 3-75KW |

The corrosion resistant chemical pump can be used for delivering highly corrosive medium in any concentration, including vitriol, hydrochloric acid, hydrogen nitrate, acetic acid, aqua regia,alkali, strong oxidant,organtic solvent,ect.

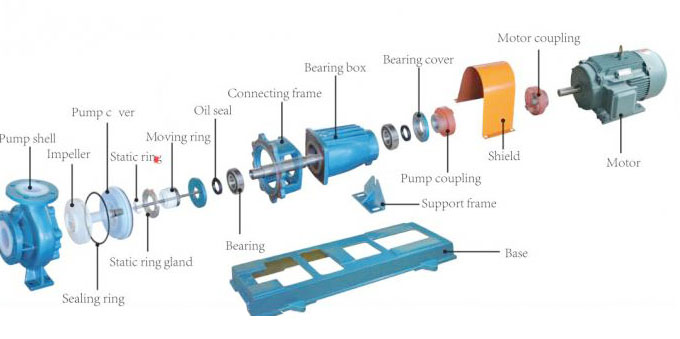

The IHF Series are single-stage, single suction and fluorplastic Alloy centrifugal pumps. They are designed according to international standards. The pump has a corrosion-resistant, wear-resistant, high temperature resistant, non-aging, high mechanical strength, non-toxic decomposition, the use of the advantages of wide temperature. The pump body is made by metal housing and FEP (F46) lining, pump cover, impeller and shaft sleeve are made by integrated sintering and pressure molding of metal insert and Fluor plastic housing, shaft seal is sealed by external bellow mechanical seal.

• The pump has the advantages such as anticorrosion,wearable,anti-high temperature,high mechanical strength and toxin decomposer etc.

• The pump has an advanced and reasonable structure,corrosion-resistant,tight and reliable sealed performance, work stability,low noise and long life.

• The pump body is metal shell with FEP(F46) ling.

• Impeller and pump cover are made by integrated sintering and pressure mould of metal inset and fluorine plastic housing.

• Shaft seal is external waviness mechanical seal. Stationary seal ring is made of 99.9% Alumina ceramic or Silicone carbon.

| Model | Inlet | Outlet | Flow | Head | Power | Rotary Speed | (NPSH) |

| (mm) | (mm) | (m3/h) | m | kw | r/min | m | |

| IHF32-25-125 | 32 | 25 | 5 | 20 | 1.5 | 2900 | 2.3 |

| IHF32-25-125A | 32 | 25 | 4.5 | 16 | 1.1 | 2900 | 2.3 |

| IHF32-25-160 | 32 | 25 | 5 | 32 | 2.2 | 2900 | 2.3 |

| IHF32-25-160A | 32 | 25 | 4.5 | 28 | 1.5 | 2900 | 2.3 |

| IHF40-32-125 | 40 | 32 | 6.5 | 20 | 2.2 | 2900 | 2.5 |

| IHF40-32-125A | 40 | 32 | 5.6 | 28 | 1.5 | 2900 | 2.5 |

| IHF50-32-125 | 50 | 32 | 12.5 | 20 | 2.2 | 2900 | 3 |

| IHF50-32-160 | 50 | 32 | 12.5 | 32 | 4 | 2900 | 3 |

| IHF50-32-200 | 50 | 32 | 12.5 | 50 | 7.5 | 2900 | 3 |

| IHF65-50-125 | 65 | 50 | 25 | 20 | 3 | 2900 | 3.5 |

| IHF65-50-160 | 65 | 50 | 25 | 32 | 5.5 | 2900 | 3.5 |

| IHF65-40-200 | 65 | 40 | 25 | 50 | 11 | 2900 | 3.5 |

| IHF80-65-125 | 80 | 65 | 50 | 20 | 5.5 | 2900 | 4 |

| IHF80-65-160 | 80 | 65 | 50 | 32 | 11 | 2900 | 4 |

| IHF80-50-200 | 80 | 50 | 50 | 50 | 15 | 2900 | 4 |

| IHF100-80-125 | 100 | 80 | 100 | 20 | 11 | 2900 | 4.5 |

| IHF100-80-160 | 100 | 80 | 100 | 32 | 15 | 2900 | 4.5 |

| IHF100-65-200 | 100 | 65 | 100 | 50 | 30 | 2900 | 4.5 |

The pump is widely used with the chemical, pharmaceutical, petroleum, metallurgy, electricity, electroplating, pickling, pesticide, paper and other industries in the liquid delivery, wastewater treatment and processing acids, etc. process.

This pump can be used in transporting harsh and strong erosive medium of any density such as vitriol, hydrochloric, organic dissolvent, corrosion medium and reducing agent etc. It is one of the latest erosion proof equipments in the world.

Long Shaft Types

Short Shaft Type