Zidong ZH metal liner slurry pump is special designed for convey water and solid mixture medium. The ZH slurry pump is a single-stage, single-suction and horizontal heavy duty centrifugal slurry pump with a cantilever design.

Parts in contacting with the medium are made of latest wear-resistance 27% chrome alloy white iron with hardness 62HRC over, which has an excellent feature for maximum resistance to strong abrasive, coarse particle.

Designed for continuous conveying highly abrasive,high-hardness, high-concentration, low-corrosion slurry contain suspended solid particles, such as finished ores, refuse ores, ashes, cinders, cements, mud, mineral stones in the tailing mining,minerals recycling ,coal washing, industries of metallurgy, pulp and paper manufacture , power plant, building material,&chemical engineering, sand dredging etc.

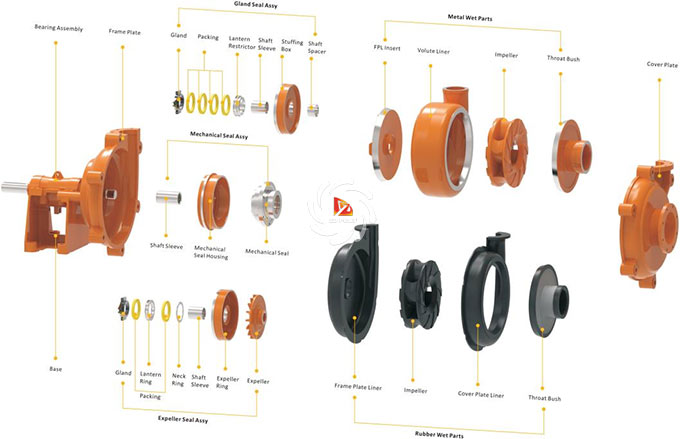

A centrifugal slurry pump is mainly composed of 3 parts:

1. The wetted parts (such as impeller, volute ,throatbush,FPL insert)

2. Shaft seal parts(such as gland packing seal, expeller seal or dynamic seal,etc.)

3. Bearing assembly parts,etc.

Bearing Assembly: A large diameter shaft with short overhang minimizes deflection and contributes to long bearing life.Only four through bolts are required to hold the cartridge type housing in the frame.

Drive Types: Such as V belt drive, gear reducer drive, fluid coupling drive, and frequency conversion drive devices.

| Pump Mainly Parts Material List | |||||

| No | Part | Material | No | Part | Material |

| 1 | Shaft | High tense steel | 12 | Volute | 27% Chrome alloy |

| – | Shaft sleeve | 3Cr13 | 13 | Discharge joint ring | Natural rubber |

| 2 | Clamp bolts | Zinc plated steel | 14 | Volute liner seal | Natural rubber |

| 3 | Base | Ductile iron | 15 | Intake joint ring | Natural rubber |

| 4 | Bolts,studs | Zinc plated steel | 16 | Expeller | 27% Chrome alloy |

| – | Bearing body | Cast iron | 17 | Frame plate liner insert | 27% Chrome alloy |

| 5 | Gland/Split gland | Cast iron | 18 | Throatbush | 27% Chrome alloy |

| 6 | Frame plate | Ductile iron | 19 | Cover plate | Ductile iron |

| 7 | Expeller ring | 27% Chrome alloy | 20 | Cotter | Cast iron |

| 8 | Expeller ring seal | Natural rubber | – | End cover | Color zinc plated |

| 9 | Volute liner seal | Natural rubber | – | Labyrinth cover | Color zinc plated |

| 10 | Impeller | 27% Chrome alloy | – | Lantern ring | 1Cr18Ni9TI |

| 11 | Cover plate bolt | Zinc plated steel | – | Bearing | Top brand |

• Cantilevered horizontal centrifugal slurry pump

• Double casing slurry pump

• Wear resistant metal wet end parts for coarse solids slurry with long service life and high efficiency

• Wide options of impellers of standard 5vanes,4vanes high efficiency and 2vanes non-clogging.

• Available with gland seal, centrifugal seal or mechanical seal

• Famous brand bearing components can improve reliability, prolong bearing life and reduce lubrication cost

• Grease lubrication

• Eight positions of discharge branch at intervals of 45 degree

• Drive types: Different connection methods (DC,CR,ZVZ,CV) with motor for selection ,satisfy the requirements on different installation condition and different capacity & head.

• Can be installed in multistage series

• Low cost of ownership

• The pump has variety of combinations of lining and impeller to adapt to different medium characteristic.

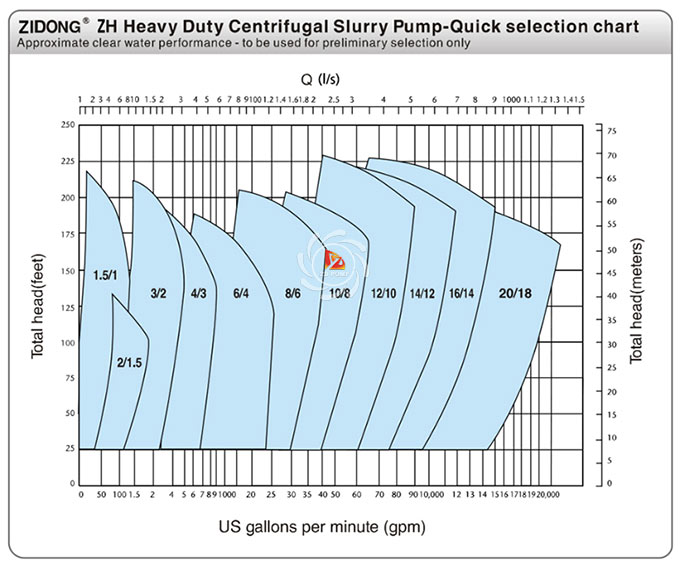

| Model | Max Power(kw) | Zh Series Clear Water Performance | ||||

| Capacity | Head | Speed | Max. Eff η% | NPSH | ||

| (m3/h) | H(m) | n(r/min) | (m) | |||

| ZH-1.5×1B | 15 | 12.6~28.8 | 6~68 | 1200~3800 | 40 | 2~4 |

| ZH-2×1.5B | 15 | 32.4~72 | 6~58 | 1200~3200 | 45 | 3.5~8 |

| ZH-3×2C | 30 | 39.6~86.4 | 12~64 | 1300~2700 | 55 | 4~6 |

| ZH-4×3C | 30 | 86.4~198 | 9~52 | 1000~2200 | 71 | 4~6 |

| ZH-4×3D | 60 | |||||

| ZH-6×4D | 60 | 162~360 | 12~56 | 800~1550 | 65 | 5~8 |

| ZH-6×4E | 120 | |||||

| ZH-8×6E | 120 | 360~828 | 10~61 | 500~1140 | 72 | 2~9 |

| ZH-10×8ST | 560 | 612~1368 | 11~61 | 400~850 | 71 | 4~10 |

| ZH-12×10ST | 560 | 936~1980 | 7~68 | 300~800 | 82 | 6 |

| ZH-14×12ST | 560 | 1260~2772 | 13~63 | 300~600 | 77 | 3~10 |

| ZH-16×14ST | 560 | 1368~3060 | 11~63 | 250~550 | 79 | 4~10 |

| ZH-16×14TU | 1200 | |||||

| ZH-18×16ST | 560 | 2160~5040 | 8~66 | 200~500 | 80 | 4.5~9 |

| ZH-18×16TU | 1200 | |||||

| ZH-20×18TU | 1200 | 2520~5400 | 13~57 | 200~400 | 85 | 5~10 |

The ZH series centrifugal horizontal slurry Pump is the pump for highly abrasive/density slurries in processes from cyclone feed to regrind, mill discharge, flotation, mine drainage and tailing in minerals plants plus other industrial applications, Sometimes, it could also be used in dredging of settling lagoons and pumping of drilling mud etc.

| • Mining • Mineral processing • Construction • Chemical and Fertilization • Power generation |

• Phosphate matrix fertilization • Pulp and paper • Waste sludge • Paper mill wastes and liquors • Precipitated CaCO3 |

• Plaster • Bottom/fly ash, lime grinding • Dirty water • Pulp and paper • Oil and gas |

| • Waste water treatment • Ball mill discharge • Rod mill discharge • SAG mill discharge • Fine tailing |

• Flotation • Heavy media process • Minerals concentrate • Mineral sands • Coal-washing plant |

• Coarse sand • Coarse tailing • Dredging • FGD • Wet crushers applications |

| • Wet scrubber systems • Process chemical • Iron and Steel • Ni acid slurry • Fracking slurries |

• Clay and sand slurries • Kaolin clay • Carbon slurry • Lime mud • Oil sands |

• Phosphoric acid |