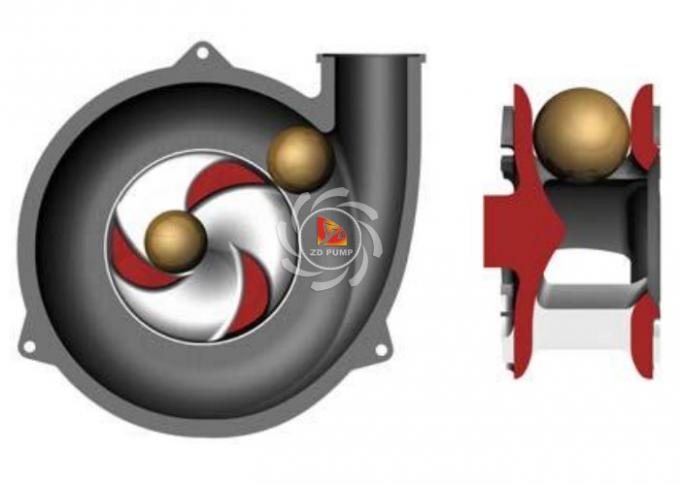

ZG(H) series adopts international advanced technology, non-clogging design with big flow channel and 3-Vane high efficiency closed impeller. Large solid particles are allowed.

ZG(H) Series Sand Gravel Pump is horizontal single-casing gravel pump with wide channel to transfer sand, slurries or gravels with big particle size. The wet parts are made of Ni-hard and high-Chrome alloys to ensure long service life. It has superior performance than common pumps in dredging, sand mining, barge loading and mineral processing etc.

• Our ZG,ZGH sand gravel pumps are the series products introduced from international high technique. All spare parts are 100% replaced with international parts.

• Zidong sand pumps are designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumps by a common slurry pump.

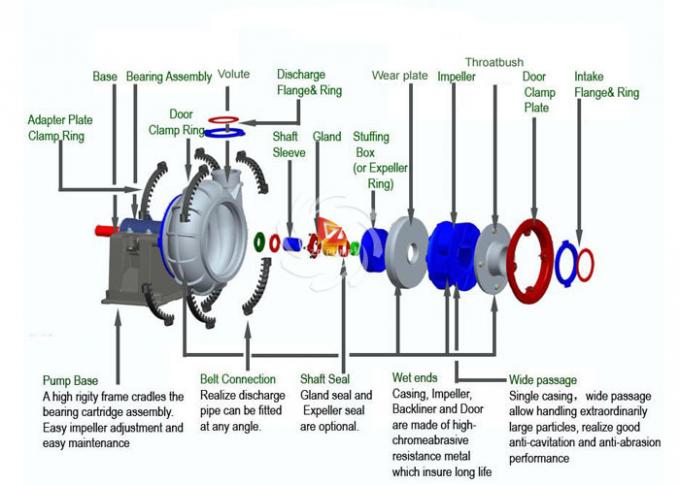

• Construction of this pump is of single casing connected by means of clamp bands and wide wet-passage.

• The wet-parts are made of Ni-hard high chrom abrasion-resistance alloy.

• The discharge direction of pump can be oriented in any direction of 360°.

• This type of pump possesses the advantages of easy installation and operation, good performance of NPSH and abrasion resistance.

• 3 Vanes big passing channel with extra thick wall.

• Bearing Assembly – A large diameter shaft with short overhang minimizes deflection & contributes to long bearing life.

• Casing – Single casing be made of high-chrome alloy, provide long wear time.

• Impeller – 3 vanes impeller, processing larger solids easily. The impeller and casing are threaded connection,no need nuts.

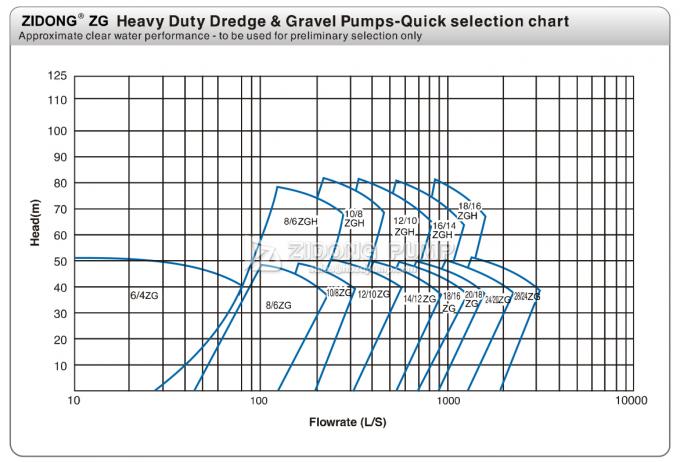

High efficiency and high head designs are also available.

• Cover Plate – Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

• One-Piece Frame – A very robust one-piece frame cradles the cartridge type bearing and shaft assembly.

An external impeller adjustment mechanism is provided for easy adjustment of impeller clearance

| Model | ZG Series Clear Water Performance | ||||||

| Max. Power (kw) |

Capacity (m3/h) |

Head (m) |

Speed (r/min) |

Max. Eff% |

NPSH (m) |

Max Size Passage (mm) |

|

| ZG-6×4D | 60 | 36-250 | 3.5-51 | 600-1400 | 50 | 3.5 | 82 |

| ZG-8×6E | 120 | 180-540 | 10-48 | 800-1400 | 50 | 4.5 | 127 |

| ZG-10×8F | 260 | 180-820 | 13-50 | 500-1000 | 65 | 7.5 | 178 |

| ZG-10×8S | 560 | 180-820 | 13-50 | 500-1000 | 65 | 7.5 | 178 |

| ZG-12×10G | 600 | 360-1200 | 11-58 | 400-850 | 70 | 4.5 | 220 |

| ZG-14×12G | 600 | 500-3000 | 6-66 | 300-700 | 68 | 4.5 | 241 |

| ZGH-10×8S | 560 | 750-1300 | 18-80 | 500-950 | 68 | 7.5 | 180 |

| ZGH-12×10G | 600 | 1400-2700 | 28-78 | 350-700 | 72 | 8 | 210 |

| ZG-16/14G | 600 | 720-3600 | 18-45 | 300-500 | 70 | 3-9 | 230 |

| ZGH-16×14TU | 1200 | 700-3400 | 20-72 | 300-500 | 72 | 3-6 | 230 |

| ZG-18×16TU | 1200 | 700-4320 | 12-48 | 250-500 | 72 | 3-6 | 254 |

They are suitable for deliverinng slurries in Mining, Explosive-sludge in metal melting, dredging in dredger and course of rivers, and other fieldes.

• Sand and gravel

• Hydraulic mining

• Slag granulation

• Tunneling

• River and pond dredging

• Heavy refuse removal

• Large particle or low NPSHA applications