Type ZG(H) pumps are of high-head ones.

ZGH series sand pumps have achieved extra high head for special working conditions. It is mainly used for long distance delivery with thicker wall in more durable working life and higher efficiency.

Zidong ZGH high pressure durable design coarse sand suction pumps are designed for continuously handling the most difficult higher abrasive slurrieswhich contain too big solids to be pumps by a common slurry pump.

Zidong Pump high pressure gravel pumps are designed for long life, efficient operation and ease of maintenance.

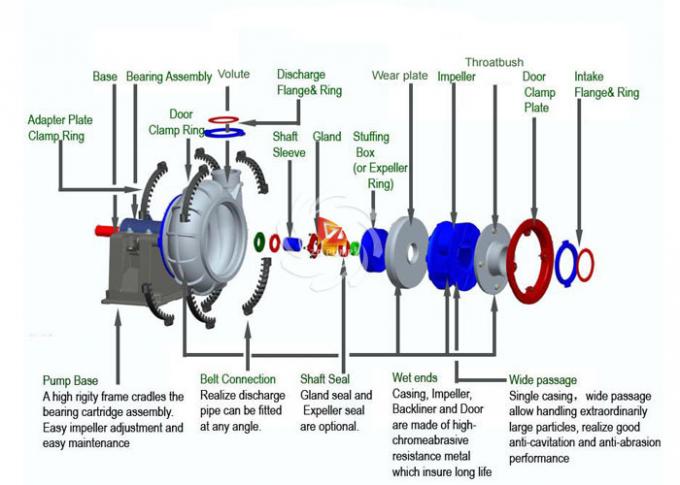

Gravel pumps have high-chrome wet ends with expeller or stuffing box seal arrangements.

• The shaft is designed with a short overhang to reduce shaft deflection and minimise vibration;

• Grease-purged piston rings to help seal contaminates out of bearing housing;

• Enclosed impellers to maximise efficiency;

• Pump-out vanes on both shrouds to minimise re-circulation and reduce stuffing box pressure;

• High chrome liquid ends, interchangeable hard metal impellers;

• Easy assembly and disassembly of liquid end;

• Minimal parts & simple design.

The pump body(casing & impeller) made of 27% high chrome alloy, the extra thick pump case let the pump anti-wear and need lowest maintenance cost.

| Parts Name | Materials |

| Throatbush | 27.5% High Chrome Alloy |

| Impeller | 27.5% High Chrome Alloy |

| Back Liner | 27.5% High Chrome Alloy |

| Volute | 27.5% High Chrome Alloy |

| Stuffing Box | HT200 |

| Door Clamp Plate | QT500-7 |

| Pump Base | QT500-7 |

| Bearing Assembly | SKF/Timken (Standard) |

| Belt Connection | 25# Steel |

| Model | ZG Series Clear Water Performance | ||||||

| Max. Power (kw) |

Capacity (m3/h) |

Head (m) |

Speed (r/min) |

Max. Eff% |

NPSH (m) |

Max Size Passage (mm) |

|

| ZG-6×4D | 60 | 36-250 | 3.5-51 | 600-1400 | 50 | 3.5 | 82 |

| ZG-8×6E | 120 | 180-540 | 10-48 | 800-1400 | 50 | 4.5 | 127 |

| ZG-10×8F | 260 | 180-820 | 13-50 | 500-1000 | 65 | 7.5 | 178 |

| ZG-10×8S | 560 | 180-820 | 13-50 | 500-1000 | 65 | 7.5 | 178 |

| ZG-12×10G | 600 | 360-1200 | 11-58 | 400-850 | 70 | 4.5 | 220 |

| ZG-14×12G | 600 | 500-3000 | 6-66 | 300-700 | 68 | 4.5 | 241 |

| ZGH-10×8S | 560 | 750-1300 | 18-80 | 500-950 | 68 | 7.5 | 180 |

| ZGH-12×10G | 600 | 1400-2700 | 28-78 | 350-700 | 72 | 8 | 210 |

| ZG-16/14G | 600 | 720-3600 | 18-45 | 300-500 | 70 | 3-9 | 230 |

| ZGH-16×14TU | 1200 | 700-3400 | 20-72 | 300-500 | 72 | 3-6 | 230 |

| ZG-18×16TU | 1200 | 700-4320 | 12-48 | 250-500 | 72 | 3-6 | 254 |

• Sand and gravel

• Hydraulic mining

• Sugar beet

• Root vegetables

• Slag granulation

• Tunneling

• River and pond dredging

• Heavy refuse removal

• Large particle or low NPSHA applications