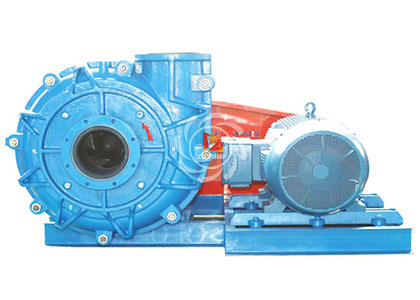

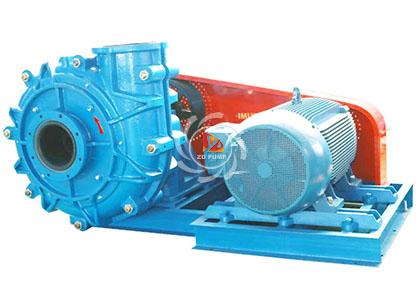

ZHR rubber liner slurry pump is ideal solution for convey water and solid mixture medium.

Suitable for conveying fine particles and corrosive liquids that contain suspended particles.

This series of pump guarantees excellent performance including wear resistance, chemical resistance , waterproof and higher operating temperature range from -40-75.

The ZHR series slurry pumps have the features on replaceable wear-resistant metal liners. Basing on medium condition can choose different materials of natural Rubber ZR26, ZR55, ZR33. And more, OEM material is available: ZR08, ZS42, ZS10, ZS12, ZS01, ZS02, ZS21,ZS31, ZU03,ZU27 etc.

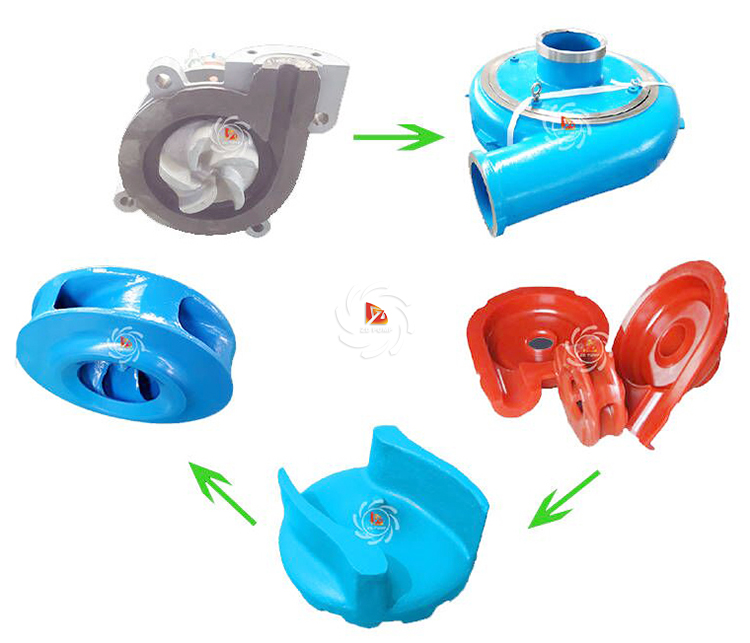

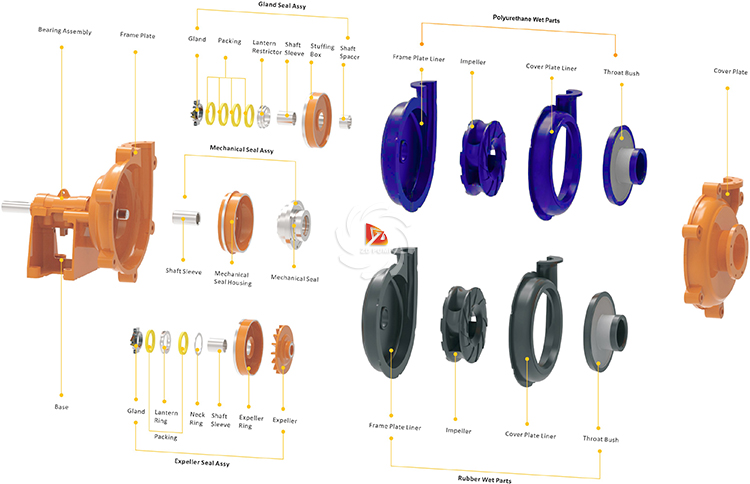

1. High Interchangeable of Wet Parts:

• Impeller: Nature rubber and polyurethane, even metal impellers are completely interchangeable. Impellers can be produced from 2 vans to 6 vans as required. High efficiency, high head and OEM designs are also available.

• Liner: Nature rubber and polyurethane, even metal liners are completely interchangeable. Easily replaceable liners are bolted, not glued, to the casing for positive attachment and east of maintenance.

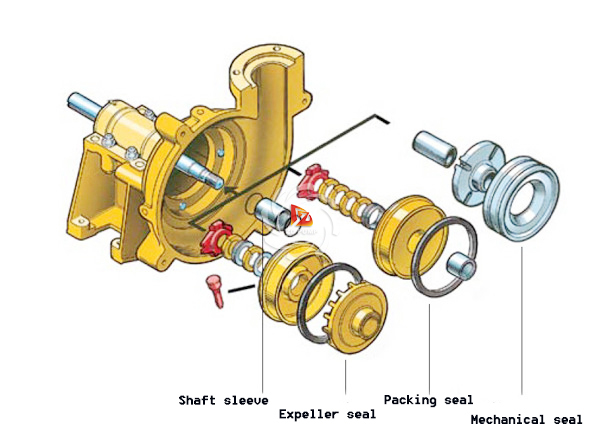

2. Modular Design, Easy To Maintain; Low Spare Cost Due To High Standardization:

• Pump Casing: Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety.

• Frame Base: A very robust one-piece frame cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearance.

• Bearing Assembly: A large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame.

3. Sealing Type: Packing Seal, Expeller Seal And Mechanical Seal Are Available Forchoice.

A hundred, heavy duty corrosion-resistance sleeve with “0-ring” at both ends protects the shaft. A slip fit allows the sleeve removed or installed quickly.

| No | Part | Material | No | Part | Material |

| 1 | Shaft | High tense steel | 12 | Volute Liner (Cover&Frame) | Natural rubber or Customized |

| – | Shaft sleeve | 3Cr13 | 13 | Discharge joint ring | Natural rubber |

| 2 | Clamp bolts | Zinc plated steel | 14 | Volute liner seal | Natural rubber |

| 3 | Base | Ductile iron | 15 | Intake joint ring | Natural rubber |

| 4 | Bolts,studs | Zinc plated steel | 16 | Expeller | 27% Chrome alloy |

| – | Bearing body | Cast iron | 17 | Frame plate liner insert | Natural rubber or Customized |

| 5 | Gland/Split gland | Cast iron | 18 | Throatbush | Natural rubber or Customized |

| 6 | Frame plate | Ductile iron | 19 | Cover plate | Ductile iron |

| 7 | Expeller ring | 27% Chrome alloy | 20 | Cotter | Cast iron |

| 8 | Expeller ring seal | Natural rubber | – | End cover | Color zinc plated |

| 9 | Volute liner seal | Natural rubber | – | Labyrinth cover | Color zinc plated |

| 10 | Impeller | Natural rubber or Customized | – | Lantern ring | 1Cr18Ni9TI |

| 11 | Cover plate bolt | Zinc plated steel | – | Bearing | Top brand |

| Model | Zh Series Clear Water Performance | |||||

| Max Power |

Capacity | Head | Speed | Max.Eff | NPSH | |

| (kw) | (m3 /h) | H(m) | n(r/min) | (η%) | (m) | |

| ZHR-1.5×1B | 15 | 10.8~25.2 | 7~52 | 1400~3400 | 35 | 2~4 |

| ZHR-2×1.5B | 15 | 25.2~54 | 5.5~41 | 1000~2600 | 50 | 2.5~5 |

| ZHR-3×2C | 30 | 36~75.6 | 13~39 | 1300~2100 | 55 | 2~4 |

| ZHR-4×3C | 30 | 79.2~180 | 5~34.5 | 800~1800 | 59 | 3~5 |

| ZHR-4×3D | 60 | |||||

| ZHR-6×4D | 60 | 144~324 | 12~45 | 800~1350 | 65 | 3~5 |

| ZHR-6×4E | 120 | |||||

| ZHR-8×6E | 120 | 324~720 | 7~49 | 400~1000 | 65 | 5~10 |

| ZHR-10×8ST | 560 | 540~1188 | 12~50 | 400~750 | 75 | 4~12 |

| ZHR-12×10ST | 560 | 720~1620 | 7~45 | 300~650 | 80 | 2.5~7.5 |

| ZHR-14×12ST | 560 | 1152~2520 | 13~44 | 300~500 | 79 | 2.5-7.5 |

The ZHR centrifugal horizontal rubber liner slurry pumps are designed for handing corrosive, acid or erosion slurries in mining, coal, metallurgical, power, building material,sand washing and other industrial departments.

| Iron Ore Dressing Plant | Copper Concentration Plant | Gold Mine Concentration Plant |

| Chemical Industry | Potash Fertilizer Plant | Mineral Flotation Processing Plants |

| Alumina Industry | Coal Washer | Power Plant |

| Sand and Gravel Handling | Sand Washer | Building Material Industry |

| Molybdenum Concentration Plant | Mining Concentration Plant | Ash-Handling System of Power Plant |