| Size(discharge) | 32″(800mm) | Capacity | 100~630m 3/h |

|---|---|---|---|

| Head | 79~1815m | Material | Cast Iron Or Cast Steel |

| Speed | 1450 And 2900 R / Min | Shaft Power | 40.6~2185.2KW |

• Cast iron, duct alloy, carbon steel, zinc free bronze, silicon brass or stainless steel construction (other materials available on request)

• High efficiency double suction impeller

• Durable, low noise, long life bearing

• Premium quality mechanical seal

• Electric or diesel drive

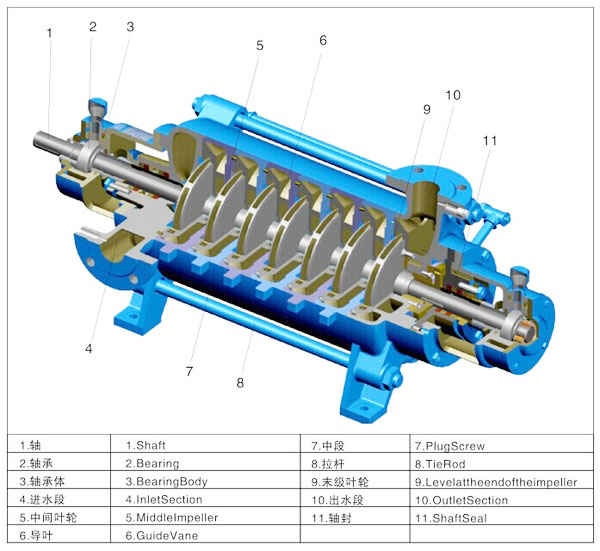

1. This DG high pressure multistage water pump is a horizontal, single suction, multi stage centrifugal pump, the suction and outlet both vertical upward. Water suction, middle, discharge section, bearing housing and pump body are bolted into one strain, and select stages according to the pump head.

2. Rotor includes shaft, impeller, shaft sleeve, balance disk, and other parts. Axis parts are connected through the flat keys and the shaft nuts. The rotor is supported by the rotor bearings or sliding bearings or in both ends, the bearing does not bear any axial,axial force is balanced by the balance disc. Bearings lubricated with grease, sliding bearings lubricated with light oil, and oil ring lubrication, and cooled by circulating water.

3. Shaft seal in the form of two kinds, mechanical seals and packing seal. When use packing seal, the packing ring should be placed at the right location, the tightness of packing must be appropriate to the liquid oozing drop by drop. Various sealing elements are in a sealed chamber, the chamber must be filled with some water, as water seal, water cooled or water lubrication. At the seal there is reserved sleeve, to protect the shaft.

4. From the motor direction, the pump is clockwise rotation

| Model | Capacity(m3/h) | Head(m) | Speed(rpm) | Motor Power(kw) | Impeller Dia(mm) |

| 6-25*4 | 6.3 | 100 | 2950 | 7.5 | 139 |

| 6-25*5 | 6.3 | 125 | 2950 | 7.5 | 139 |

| 6-50*4 | 6.3 | 200 | 2950 | 18.5 | 198 |

| 12-25*4 | 12.5 | 100 | 2950 | 11 | 146 |

| 6-80*3 | 6 | 240 | 2950 | 18.5 | 235 |

| 12-80*4 | 12.5 | 320 | 2950 | 45 | 235 |

| 25-30*3 | 25 | 90 | 2950 | 15 | 160 |

| 46-30*5 | 46 | 150 | 2950 | 37 | 162 |

| 85-67*4 | 85 | 268 | 2950 | 110 | 235 |

| 120-50*5 | 120 | 250 | 2950 | 132 | 213 |

| 150-30*8 | 150 | 240 | 2950 | 160 | 172 |

| 150-100*6 | 150 | 600 | 2950 | 400 | 289 |

| 200-100*6 | 200 | 600 | 2950 | 560 | 290 |

| 280-65*6 | 280 | 390 | 1480 | 500 | 430 |

| 300-45*4 | 300 | 180 | 1480 | 200 | 360 |

| 150D30*6 | 155 | 180 | 1480 | 132 | 305 |

The DG high pressure fire pumps apply to transport hot water and other water-like liquids whose impurity content is lower than 1% and grit size is smaller than 0.1mm and whose chemical and physical characteristics is similar to clean water.

1. Apply for medium and low pressure boiler feed water.

2. Water supply and discharge in factories and mines

3. Water supply and discharge in high-rise buildings

4. Fire water supply in constructions

5. Long distance delivery

6. Cyclic pressurization in production