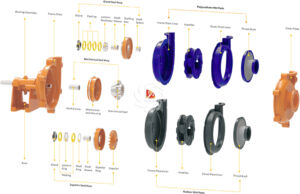

Pump overview

Zidong Pump (Brand Name) ZHR rubber liner corrosion resistance mineral slurry pumpsare single-stage, cantilevered, double casing, horizontal, centrifugal slurry pump.

They were designed for handing corrosive, acid or erosion slurries in mining, coal, metallurgical, power, building material,sand washing and other industrial departments.

The wear parts are made of material natural Rubber ZR26, ZR55, ZR33. And more, OEM material is available, eg. ZR08, ZS42, ZS10, ZS12, ZS01, ZS02, ZS21,ZS31, ZU03,ZU27 etc,

In view of the features on replaceable wear-resistant metal liners, the pump has variety of combinations of lining and impeller to adapt to different media characteristics.

Pump Structure

| Part name | Material | Part name | Material |

| Shaft | High tense steel | Expeller ring | Natural rubber |

| Shaft sleeve | 3Cr13 or as designed | Cover plate liner | Natural rubber |

| Cover plate | Ductile iron | Impeller | Natural rubber |

| Frame plate | Ductile iron | Frame plate liner | Natural rubber |

| Expeller | 27% Chrome alloy | Throatbush | Natural rubber |

| Gland/Split gland | Cast iron | Labyrinth cover | Color zinc plated |

Pump Features

1. Horizontal, cantilevered, centrifugal, single stage slurry pump design.

2. International brand replaced pump, 100% same technique design, structure, and performance.

3. Thick rubber and polyurethane pump lining are available and can be replaced with each other.

4. Double casing, liner insert can be replaced by metal liner or rubber one.

5. Different connection methods(DC, CR, ZVZ, CV) with motor to satisfy different requirements.

6. Discharge can be adjusted by 8 directions every 45 degree.

Application

● Copper Concentration Plant

● Gold Mine Concentration Plant

● Molybdenum Concentration Plant

● Potash Fertilizer Plant

● Mineral Flotation Processing Plants

● Alumina Industry

● Coal Washer

● Power Plant

● Sand and Gravel Handling

● Building Material Industry

● Chemical Industry

● Mining concentration plant

● Ash-handling system of power plant