Slurry pump is one kind of centrifugal pump used for convey water and solid mixture medium,It can be used in mining, electric power, metallurgy, coal, environmental protection and other industries to transport slurry containing abrasive solid particles.

Due to the general presence of solid particles in the transport medium and the poor application conditions, the service life of slurry pumps is generally low, which can lead to a lot of downtime as well as expensive maintenance and spare parts, so it is particularly important to choose a suitable slurry pump.

1.Determine the model according to the site working conditions and parameters:

There are many types of abrasion resistant slurry pumps, so provide the correspond flow and head and other parameters to choose the right slurry pump.

2.According to the transport medium situation choose slurry pump material:

The slurry pump wet parts are mainly made of metal materials A05 and natural rubber.

A05 high chrome alloy: the most widely used in slurry pumps, with a heat treatment hardness of HRC 62+ and a chromium content of not less than 27%. It is resistant to wear and tear, has a long life span.

Natural rubber: good abrasion and corrosion resistance, mainly suitable for fine particle bits without sharp school angles, also suitable for conveying weak acid liquids.

Zidong slurry pump, according to different working conditions, can freely choose the suitable lining. 27% high chrome alloy + natural rubber + polyurethane, high interchangeability.

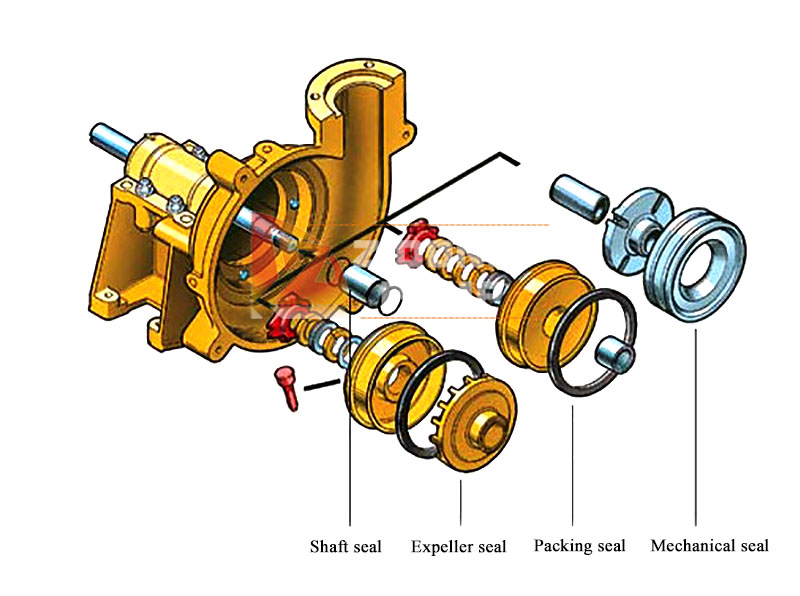

3.Select the ideal sealing assembly according to the abrasion of the slurry:

Reliable shaft seal, packing seal, expeller seal, or mechanical seal are available;

4. Choice of different motor connections:

Different connection methods (ZVZ, DC, CV, CRZ) with motor for selection, satisfy the requirements on different installation condition and different capacity & head.

5.To find out more about products and services, please contact our experienced team for expert guidance to discuss your pump system requirements.