Recently, we completed two ZN450 dredging pumps and 18-16T-ZG gravel pumps for our customers. These two pumps are mainly used for sand pumping, dredging and other highly abrasive application projects. The main wear parts are made of high-chromium alloy, which has good wear resistance.

In sand mining, river dredging and other similar working conditions, a strong wear-resistant pump is one of the main equipment, in order to choose a most suitable pump, we will simply compare the two different types of pump Zidong pump industry.

First of all, the main wear parts of the two pumps both are wear-resistant high chromium alloy material, suitable for sand suction, dredging, and other industries; But due to the differences in design, their performance is different, you can see the difference between the two pumps in table below:

| Model: | ZN450 | 18/16T-ZG |

| Max flow: | 4600m³/h | 4000m³/h |

| Head range: | 40-67m | 12-48m |

| Intake size: | 24 inch | 18 inch |

| Discharge size: | 18 inch | 16 inch |

| Type of impeller: | Close 3/5 vanes | Close 5 vanes |

| Max solid size: | 125mm (5 vanes) | 254mm |

| Max power: | 1500kw | 1200kw |

| Lubrication: | Oil lubrication | Grease lubrication |

| Weight: | 11000kgs | 7200kgs |

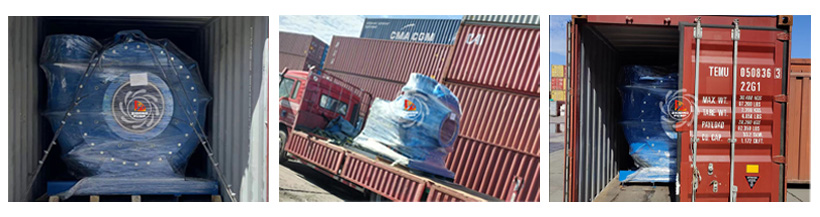

Our pump will pass a complete quality inspection process before delivery, including material composition test of the wear parts, material hardness test, impeller dynamic balance test, static pressure test, performance test and so on, to ensure customer receive a high quality pump.

We hope that the above comparison can help you understand the two pumps better. If you have any questions about our pumps, or feel which pump is suitable for your needs, please contact us. Our experienced engineers will provide you with a complete budget minimization and benefit maximization solutions.