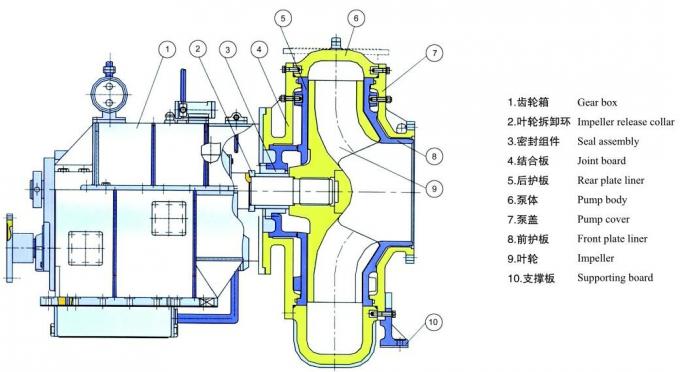

ZN series dredge pumps are particularly suitable for dredging, filling and other operations in rivers and lakes.It fully meets the requirements of the dredger for mud pumps.They are composed of a pump head, reducer gear box, high elastic coupling, and marine transmission monitoring system.

ZN dredge pump is a new type of sand sludge pump designed & manufactured by China.

ZN type dredge pump is horizontal, single-stage cantilevered structure, which is designed to meet the requirement of the contractor demanding and comprehensive dredging requirement.

ZN type dredge pump impeller passage is very wide, to continuous pumping gravel or high plastic clay and not happens jam.

The minimal amount of wear parts design in these dredge pumps results in reduced wear, long life and lower maintenance which translates into less downtime, significant cost savings and dredging good performance within high efficiency.

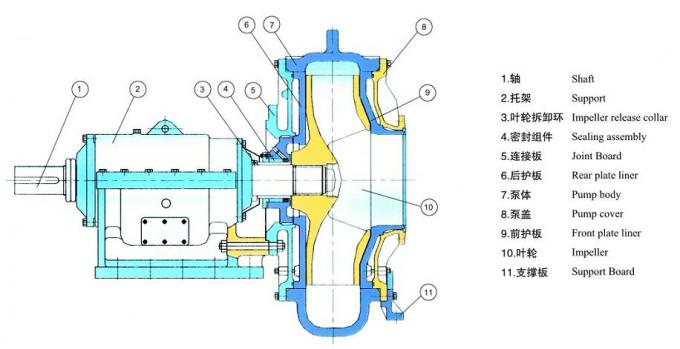

● ZN dredge pump is horizontal , single-stage, cantilevered, single casing structure;

● Hard wear resistance, longer wear life, wet parts are made of 27% high chrome wear resistance alloy;

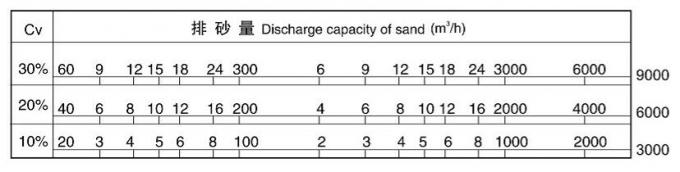

● Wide passage, large capacity and high head, excellent dredging performance and strong through-put;

● Large dredging depth, high density of dredging mud, good NPSH and strong suction lift ability:

● ZN model dredge pump can meet different requirements according to various dredger structure, and has wide applicability;

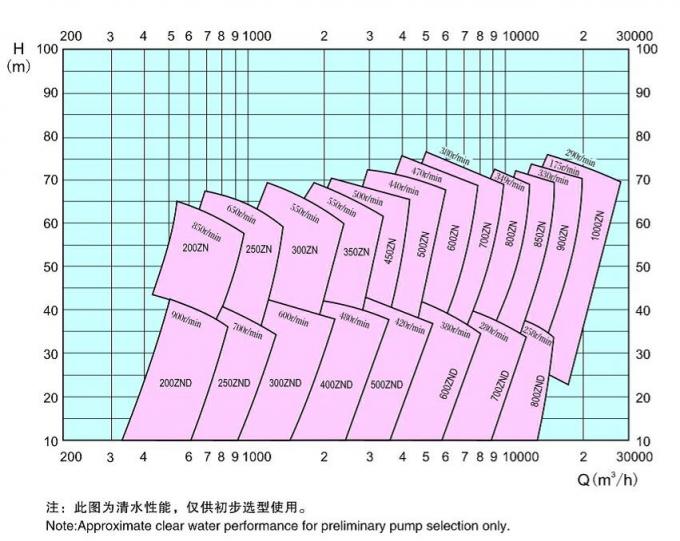

● By changing pump speed or impeller diameter, the capacity and head can be adjusted;

● The shaft seals can be gland seal or Lip seal;

● The discharge branch can be positioned at interval of 45 degrees by request and oriented to any eight positions to suit installations and applications;

● The pump can be directly matched with either motor or diesel engine;

● Simple & reliable construction, easily disassembly & assembly,convenient maintenance;

● Reliable sealing without leakage.

Centrifugal dredging pump with bracket type

Centrifugal pump integrated gearbox type

| Model | ZN dredging pump performance table | ||||||

| Capacity | Head | Speed | Efficiency | NPSH | Outlet/Inlet Diameter | Max Particles Size | |

| (m3/h) | H(m) | n(r/min) | η(%) | (m) | (mm) | (mm) | |

| ZN250 | 300-1600 | 35-80 | 490-750 | 70-74 | 4 | 250/350 | 144 |

| ZN300 | 1800-3000 | 40-65 | 425-550 | 74-78 | 4 | 300/450 | 241 |

| ZN350 | 2600-3000 | 40-65 | 400-550 | 74-78 | 4.5 | 350/450 | 205 |

| ZN400 | 2800-3200 | 20-40 | 400-550 | 74-78 | 4.5 | 400/450 | 200 |

| ZN450 | 3200-3850 | 40-67 | 350-500 | 76-80 | 4.5 | 450/600 | 254 |

| ZN500 | 4500-5500 | 40-65 | 350-450 | 78-80 | 4.8 | 500/650 | 250 |

| ZN600 | 5000-9500 | 55-80 | 280-420 | 84-85 | 6 | 600/660 | 280 |

| ZN700 | 8000-12000 | 60-85 | 280-380 | 83-85 | 6 | 700/760 | 300 |

| ZN800 | 10000-15000 | 60-70 | 260-360 | 79-80 | 6 | 800/850 | 320 |

| ZN900 | 12000-19000 | 50-75 | 280-330 | 85-87 | 6 | 900/960 | 340 |

| ZN1000 | 16000-25000 | 23-76 | 181-290 | 85-87 | 6 | 1000/1200 | 350 |

Zidong horizontal dredge pumps are designed for heavy duty applications such as mining, power sector, dredging river, and tailings as well as specialty applications, which are used for continuous pumping of high abrasive, high density sand and gravels.

| Mineral Processing | Power Generation | Aggregate |

| Ash Handling | Flue Gas Desulfurization | Thickener & Tailings |

| Mine Dewatering | Industrial Slurries | Dredge |