| Size(discharge) | 32″(800mm) | Capacity | 60~6000 M 3/h |

|---|---|---|---|

| Head | 12~160m | Material | Cast Iron Or Cast Steel |

| Speed | 1450 And 2900 R / Min | Motor Power | 7.5-1800 Kw |

The S(SLOW) serial single stage double-suction centrifugal pump has the high head, large flow characteristics, widely used in engineering. It is late-model energy-saving horizontally split pump newly developed by us on the base of the old style double suction pump at home and abroad.

Our SLOW series single-stage double-suction split volute centrifugal pump is produced by our company based on importing the advanced technology from Germany in accordance with the market demand. By using the original and modified impeller and cutting, the pump boasts a full and wide range of spectrum and high service efficiency.

The water pump can provide the working points of any flow and lift head required by the user within the

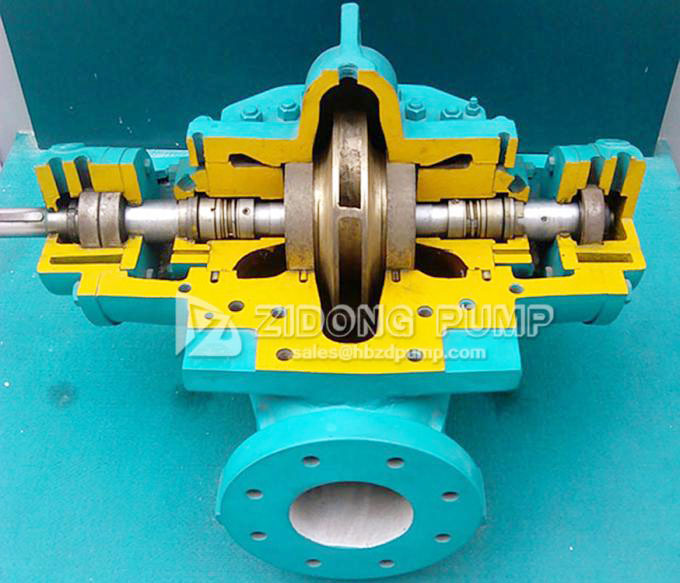

spectrum performance range. SLOW pump adopts a hydraulic model with the self-balancing axial force and radial force, which is the best both at home and abroad currently. It boasts stable performance ,high efficiency, compact structure,small vibration,strong resistance to pressure of pump body and being easy for installation and maintenance.

• Compact structure, less room occupied, compressed axial size.

• Low vibration, low noise, the following meansure to reduce vibrates and noise.

A. The pump casing is double-volute structure.

B. Rotor part axial size is short and fine rigidity.

C. The shaft uses high precise imported bearing.

Pump Casing: Cast iron, Ductile cast iron, Cast steel, Stainless steel

Impeller: Cast iron, Bronze, Brass, Stainless steel Shaft: C-steel, Cr-steel

Wear Ring: Cast iron, Brass

| Model | Capacity | Head | Speed | NPSHr | Efficiency | Power | Weight | Diameter(mm) | ||

| Q(m³/h) | H(m) | n(rpm) | (m) | η(%) | Shaft Power | Motor Power | (kg) | Inlet | Outlet | |

| 250S65 | 360 | 71 | 1450 | 6.7 | 75 | 92.8 | 132 | 831 | 250 | 200 |

| 485 | 65 | 79 | 108.5 | |||||||

| 612 | 56 | 72 | 129.6 | |||||||

| 250S65A | 342 | 61 | 1450 | 6.7 | 74 | 76.8 | 110 | 831 | 250 | 200 |

| 468 | 54 | 77 | 89.4 | |||||||

| 540 | 50 | 75 | 98 | |||||||

| 250S39 | 360 | 42.5 | 1450 | 6.7 | 76 | 54.8 | 75 | 500 | 250 | 200 |

| 485 | 39 | 83 | 62 | |||||||

| 612 | 32.5 | 79 | 68.6 | |||||||

| 250S39A | 324 | 35.5 | 1450 | 6.7 | 74 | 42.4 | 55 | 490 | 250 | 200 |

| 468 | 30.5 | 79 | 49.3 | |||||||

| 576 | 25 | 77 | 50.9 | |||||||

| 250S24 | 360 | 27 | 1450 | 6.7 | 80 | 33.1 | 45 | 370 | 250 | 200 |

| 485 | 24 | 86 | 36.8 | |||||||

| 576 | 19 | 82 | 38.4 | |||||||

| 250S24A | 342 | 22.2 | 1450 | 6.7 | 80 | 25.8 | 37 | 370 | 250 | 200 |

| 414 | 20.3 | 83 | 27.6 | |||||||

| 482 | 17.4 | 80 | 28.6 | |||||||

| 250S14 | 360 | 17.5 | 1450 | 6.7 | 80 | 21.4 | 30 | 320 | 250 | 200 |

| 485 | 14 | 85 | 21.7 | |||||||

| 576 | 11 | 78 | 22.1 | |||||||

| 250S14A | 320 | 13.7 | 1450 | 6.7 | 78 | 15.4 | 22 | 320 | 250 | 200 |

| 430 | 11 | 82 | 15.8 | |||||||

| 504 | 8.6 | 75 | ||||||||

This series is widely used in dredging pump booster, water jet system,waterworks, irrigation, draining pump suction, electric power station, air-conditioning circulation water, industrial water supply system, fire fighting system, shipbuilding industry, and general use in oil refining industry.

1. Pumping clean water or liquids similar to water in physical and chemical properties.

2. Delivering seawater, rain water and industrial waste water containing suspending particles (pump by using special parts).

3. Water supply for tap water plant, air-conditioning circulation system, building, irrigation, dewatering pump station, power station, industrial water supply system, firefighting, boating industry, and common applications in oil refinery.